Nikkon Engineering solution specializes in producing both standard valve components and parts that are specially made to meet the needs of our clients. All of our valve components go through extensive testing to ensure they match the highest industry standards, demonstrating our dedication to quality. Nikkon Engineering solution is one of India's top manufacturers of valve components and customized forged valves, serving a range of sectors with an emphasis on the oil and gas sector. Control valves, butterfly valves, ball valves, customized forged valves, check valves, and globe valves are among the variety of valves frequently used in this business. Our team of professionals is committed to helping you choose the best valve components for your particular needs.

| Size | 1/4" -4" (DN8-DN100) |

| Material | SS201, SS304, SS316(CF8, CF8M) |

| Pressure | 1000psi, PN16 |

| Connection | F/F threaded |

| Type of thread | NPT, BSPT, BSP, PT, DIN2999 ETC |

| Sealing | PTFE, RPTFE, PPL ETC |

In assembly stem engage is locked with wedge on top side and stem operate using handle wheel assembly, to seal the joint bet, body and bonnet.

| Range: 1/2" - 60" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

Actuator Stem is used for on-off or throttling control of noncorrosive or mildly corrosive gases. It is designed to meet low-pressure gas application requirements in many varied industries.

| Range: 1 1/2" - 36" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

Spline Shaft is used for on-off or throttling control of noncorrosive or mildly corrosive gases. It is designed to meet low-pressure gas application requirements in many varied industries.

| Range: 2" - 48" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

Packing glands in valves are used to create a tight seal around the valve stem to prevent fluid or gas from leaking out, particularly where the stem exits the valve body. This compression keeps the valve stem sealed while allowing it to rotate or move linearly as required for opening or closing the valve. Packing glands are essential for valves in high- pressure or high-temperature applications, as they help ensure reliability and safety by controlling leaks and maintaining system integrity.

| Range: 1/2” - 6” |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials SS, MS, Duplex, Super Duplex |

Quality Management System ISO 9000:2008 |

A body adaptor in valves is a component that connects the valve body to other parts, such as the actuator, stem, or other internal mechanisms, to ensure a secure and functional fit. It helps align and stabilize these parts while allowing them to operate smoothly. In many cases, the body adaptor also allows for flexibility, enabling different components to be used with the same valve body by adapting to various sizes or types of actuators or other fittings.

| Range: 1 1/2" - 16" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

The stem housing in a valve is the component that holds the stem, providing alignment and stability as it moves to open or close the valve. This housing ensures that the stem remains securely positioned and often contains packing or seals to prevent leakage along the stem.

| Range: 1 1/2" - 36" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

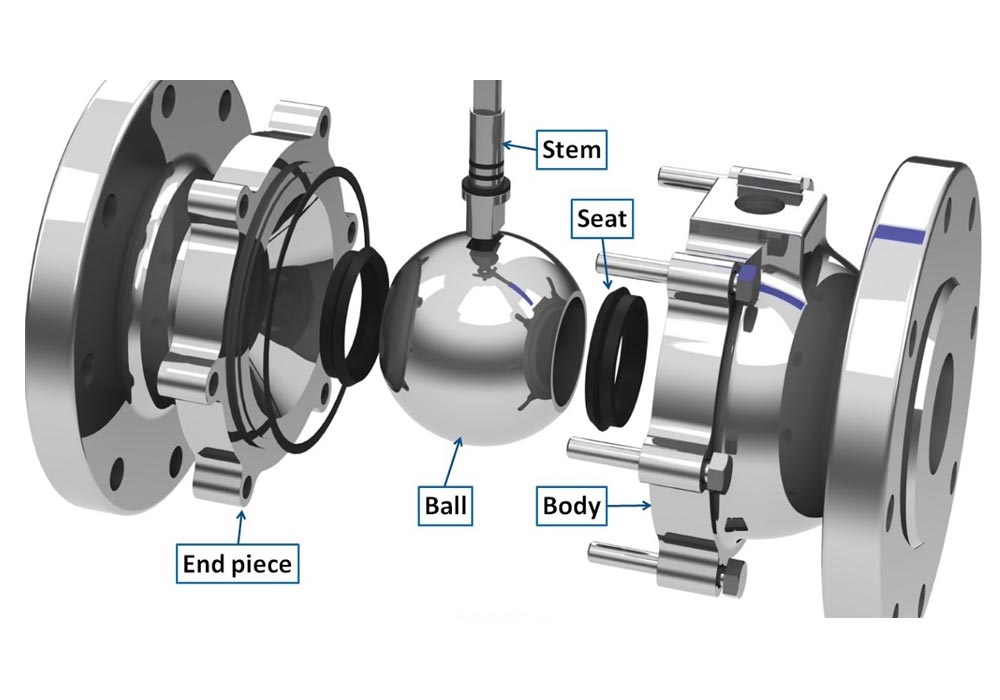

The body of a valve is its primary structural component, enclosing the internal parts and connecting to the piping system. It houses the internal components like the seat, disk, and stem, determining the valve's strength, pressure rating, and resistance to stress. Made from various materials, the valve body is critical in ensuring durability and performance under different temperature and pressure conditions.

| Range: 1 1/2" - 16" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

The Trunnion-Mounted Ball Valve (TMBV) Ball is a central component in trunnion-mounted ball valves, designed to offer stability and reduce operating torque. Unlike floating balls, which rely on fluid pressure to seal, the trunnion-mounted ball is fixed in place with support at the top and bottom. This structure allows it to handle high pressure more effectively, minimizing wear on seals and reducing the force required to operate the valve.

| Range: 1/2” - 6” |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials SS, MS, Duplex, Super Duplex |

Quality Management System ISO 9000:2008 |

The bonnet is a critical part of a valve's design, covering and sealing the valve’s internal components. Typically fastened to the valve body, the bonnet provides easy access for maintenance, repair, and inspection of internal parts like the stem and seat. Depending on the valve type and its intended application, bonnets may come in various designs, such as bolted, threaded, or welded.

| Range: 1 1/2" - 36" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

The seat ring in a valve is an essential sealing component that provides a surface for the valve's closure element (such as a ball, gate, or plug) to rest against when closed, ensuring a leak- tight seal. Usually crafted from durable materials like stainless steel, elastomers, or other resistant alloys, the seat ring maintains a secure shut-off and helps withstand high pressures, temperatures, and corrosive environments.

| Range: 1 1/2" - 12" |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials Carbon Steel, Stainless Steel, Nickel Alloy Steel, Alloy Steel |

Quality Management System ISO 9000:2008 |

A plug in the context of valves refers to a type of internal component used in certain valve designs, such as plug valves. The plug is a cylindrical or tapered device that controls the flow of fluid through the valve by rotating within the valve body. The plug typically has one or more passageways (ports) that align with the valve's inlet and outlet when the valve is open, allowing fluid to flow through. When the valve is closed, the plug rotates to block the flow.

| Range: 1/2” - 6” |

Class: 150 PSI - 2500 PSI |

| Availalbe Materials SS, MS, Duplex, Super Duplex |

Quality Management System ISO 9000:2008 |